|

|

|||||||||

![]()

| First, a bit of history is in order here. I spent quite

a bit of time doing all the calculations for these struts. Many of the manufacture's

websites out there have plenty of info on how to select the proper strut for your needs.

What a Pain! I must have spent at least 20 hours calculating and drawing and calculating

again ....yada yada yada.... I was going to post all that info here, but decided I wasn't about to answer a zillion questions from readers or argue choices and 'precise' values. There are tooooo many variables to be super accurate here. So once I was in the ballpark, I went and hunted down 'equivalent' units that were close to my calculations. The following is a chunk of data I had sent a company in Germany, one in Indonesia, and one in India. None of the engineers seemed to want to deal with the design requirements for some reason. Maybe they didn't want to be responsible for the supplied info. Anyway... here it is in 'short' form. |

The initial info I tried sending some of the companies I contacted to get answers

----------------- beginning of info first supplied to mfr'ers-----------------

|

These four photos show the bonnet being opened. At this point the bonnet required roughly 45-55 lbs. pounds to lift the trailing edge.

Initial effort to open the bonnet is greatest from it's initial closed position to about this point (roughly 10-20 degrees) Best 'guesstimate' is roughly 35-45 lbs. at this point

By this point (just short of 45 degrees) the effort starts to reduce, as the CG of the bonnet is now 'up and over' the offset pivot point of the bonnet. The bonnet in hand weight is roughly 20lbs

By this point the bonnet weight (in your hand trying to move it only 5-10 lbs. You can see the OEM stay rod supporting the bonnet in it's open position. Max open position possible with prop rod removed would be about 100 degrees. In this position, at rest (roughly 80 degrees open) The bonnet CG is probably 6-8" behind the pivot point. |

|

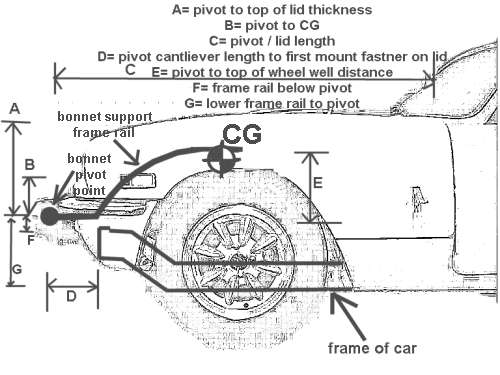

A = 12" B = 6-8" C = 58" D = ~5" E = ~ 9" F = 2" G = 8-10" ? CG to pivot = 24-26" |

| This drawing is an attempt to define the dimensions of the

bonnet compared to it's pivot point. The pivots themselves are actually buried up

inside the black rubber 'tits' in front of the chrome bumper. There is a support frame

inside the bonnet that has the pivots attached. This 'rail' assembly, bolts to the top

side of the fender wells. The dimensions are as follows A - Thickness of the bonnet from the pivot point to the top of the bonnet |

|

|

This shot shows the bonnet support frame (round tube) Remember... this tube 'hooks' and the pivot is inside the black rubber bumper in front of the chrome grill. |

|

Another shot of the tube and the 'hook' and how

it goes up inside the rubber overrider of the front bumper assembly.

This shot is to assist in figuring mounting locations for the gas strut. |

|

|

|

Another shot showing the 'box' that hoses the pivot tube (drivers side of the car) The inner fender well wall is almost perfectly in line with the outer most edge of the pivot box. The angle of the OEM stay rod (bonnet support rod) may give you an idea of the relative positions. |

|

Looking across the engine compartment at the passenger side support pivot and the inner surface of the inner fender well. |

|

Just another shot of the OEM support rod. I guess I'm looking at mounting the springs on the frame rails or right next to the pivot box, and to the bonnet pivot tubes just ahead of the wheel well. This would keep the units vertical as required to keep the seals oiled properly. |

| Two variations on function, I assume would be based as much on mount position

as gas spring power. I'm assuming we're talking about 'type 2' or type 7 configurations (per your web pages) Variation #1 - Zero initial effort to open the bonnet ... almost to the point of the bonnet opening itself when both catches (chrome handles on the sides of the bonnet ) have been released. I assume this would entail the springs being strong enough to keep the bonnet up without any other supports. Variation #2 - minimal effort to lift... assist mode... with the camlock config to lock it in the upright position (seems much safer to me) |

-----------------end of info to mfr'ers----------------

![]()

Test Setup #1 |

|

| Well for the first round of testing I'm

using a set of Stabilus units. SACHS Stabilus LIFT-O-MAT

package label part numbers reads SGSG230003* above the barcode and 92134* SACHS NORTH AMERICA

below it. This 'kit' (one strut per kit) has an eyelet on the end of the ramrod and a

ball/socket on the tube body end. The kit also contained a small metal bracket with a

clevis pin as the mount on for the ramrod end. You'll see why this mount type comes

in so handy here. They are 25" 'eye-to-eye" initial compression is 40

lbs. At full compression (8-10" stroke) the pressure rises to around 65

lbs. The drivers side radiator support rod, where it meets the original stay rod mount, was drilled out to accept a larger diameter 0.25" bolt. |

|

| This original bolt was replaced with the M10- 1/4" ball needed to mount the rod end.

|

|

| On the passenger side, I had to make a small bracket to mount the end of

the stay rod. A simple 3/16" steel strap bent at 120° with two holes drilled to fit.

|

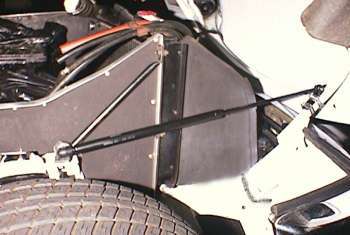

The strut mount at the bonnet tube looks like a screen door strut mount. This was simply 'hose-clamped' in position as I experimented with where on the upright I wanted to mount it. This let me adjust the pressure the strut put on the bonnet rod.

|

| At the radiator support bracket mount on the shock tower, I simply slipped my 'bent' bracket under the end and used a slightly longer bolt through it in the original holes. The radiator bracket helps to keep it from rotating. | |

| With the original stay rod in place these units where fitted to hold it in the same position. When closed, the pressure is almost directly inline with the pivot, nearly eliminating 'bending' forces of other configurations. | |

| This system easily held the bonnet open, but added very little in the way of initial opening weight reduction. | |

![]()

Test Setup #2 |

||

| Well for the second round of testing I'm using a different set of Stabilus units. SACHS Stabilus LIFT-O-MAT package label part numbers reads SG123002* above the barcode and 92020* SACHS NORTH AMERICA below it. (new # update 11/11/02) The Sachs catalog lists these as replacements for the Subaru Dl and GL wagon tailgates. They are 28.5" 'eye-to-eye" extended, (17" compressed) with an initial compression force of around 45 lbs. At full compression (10-11" stroke) the pressure rises to around 70 lbs. | ||

|

This set of struts are longer. They came

with a ball/socket end on the ramrod end, and the eyelet and same bracket as above, on the

tube body end. A clevis pin, and associated all hardware was included. You'll see

why this mount type comes in so handy in this configuration. Both sides are a 100% mirror image of each other. Three holes were drilled for each strut's mounting requirements, using 0.25"x.5" bolts.

The lower mounts are small 90° metal brackets to mount the end of the stay rod. A simple 3/16" steel strap bent at 90° with two holes drilled to fit. It's fitted tight against the box to keep it from shifting. Just make sure you're far enough out from the main frame rail to get a nut on the bolt before you drill the mount hole in the top rail. |

|

| This end style arrangement made it easy to mount, as no extra plates are required to support the strut at the fender well metalwork. There are two holes already in the fender work. The 'lower' of the two holes in the strut mount goes in the lower hole in the fender. The second hole can then be drilled to fit. | ||

| This is quite literally the balance point of the bonnet now. It's not trying to float open, and not trying to fall closed. There is about a 10 degree 'dead zone' here. |

|

| The Bonnet, when fully up, actually needed about 5-10 lbs. of push to start it closing. If you 'lift by the lever' (a major no-no.... but we all do it....) the effort is only 10 lbs. Plus there is a lot less twist to the bonnet rising when only lifting from one side. |

|

|

No stay rod is needed here. From the 'dead zone'

you can let go of the bonnet and it will open the rest of the way and cushion stop

on the strut's oil damping. THIS IS NOT TRUE OF LETTING IT CLOSE ON IT'S OWN!) It will still drop loudly! |

![]()

Test Setup #3 |

|

| Well #2 has been working very much to my

liking...so I'm going to stop here. HHmm.... Wow! they do! Well I found a use for the shorter set of struts used in test setup #1. They fit perfectly on the rear tailgate of my 1973 BGT. :-) |

|

--------------

![]()

| I've had many people tell me the 123002 units are rare

and now hard to find. I found that to be true myself when I went to add the gas springs to

my 1973 GT6 MKIII. So on my third attempt, I have found the 126003

units work well too. They are about 1.5" longer so the upper mount point had to be

changed. They are also just a bit stronger (5-15 lbs), yet still do not over power the

bonnet. On the Spit with the 123002 units, the struts were perfectly vertical. With the 126003

units, they are about 10 degrees off vertical. Picking the right upper mount point is

simply a matter of opening the bonnet to where you want it, and seeing where the top end

of the strut meets a flat surface of the inner wheel well. The 126003

units are ball and socket at both ends. So I used large fender washers on both sides of

the upper ball 'post' so it wouldn't bend and pull out of the sheet metal fender well. On

the GT6 I did weld 'tabs' on as the lower brackets rather than bolt on an 'L' bracket like

the Spitfire. You also need to hunt down a set of matching nuts (metric) for the ball socket posts as they don't come with nuts. I'm assuming on the 'stock' setup, these ball posts would have screwed into a captive nut somewhere on the vehicle. |

| A brief index of a couple of manufactures |

|

| Pravi

Auto Swing PVT Ltd. Stabilus (In German) Associated Spring Raymond AVM Inc. - terminology explained AVM Technical guide ArvinMeritor - Brackets and mounts Hahn Gassprings Izerwaren Inc. Ace Controls International - neat 'remote' release Kaller |

|

| How's this for a good reason for posting this kind of

stuff. I had visitor to this site that submitted to me the following email.

It's kind of funny, and just a coincidence, that these are the guys I just happened to

have purchased my corvette air shocks from for the rear of the GT6 about 3 months ago. ...no financial interest here... just as good group of guys...

I hope you don't mind that I post this here Tom, but it's guys like you that

keep this hobby fun! (and I'm sure the public plug can't hurt right :^) ------------------------------------

|

![]()

©1987-2010

All material copyright© Teglerizer 1996-2008last edited

3/15/08

hits since last reset